Replacement fences run the gamut from the Sears XR2424, available from Sears for about $150 and the same as the one on the Ridgid saws, to the Accufence, at about $200, to the Vega, about $210, to the Biesemeyer, about $250 for the short one. The fence that comes with almost any Sears saw from the 50s (and maybe earlier) until just before they dumped Emerson (their major floor tool supplier for > 30 years) is, well, inadequate. A brief and basically uninformative description and pricing from Woodcraft is available at their web site. The whole assembly is designed to add some precision to the process of aligning the saw blade with the miter slot. For those that don't know, PALS is a pair of studs that replace the rear trunnion bolts, teamed with an aluminum angle bracket with allen screws. I confess I haven't done the PALS conversion yet, although I did purchase the kit. You probably won't be able to get closer than about. Repeat this procedure until you get it as close as possible. Since you are unlikely to get that in the first try, loosen the trunnion bolts very slightly and using a block of wood as a punch take a tap on the trunnion assembly with a mallet. Then rotate the blade so that the marked tooth is toward the back of the table opening, and measure the distance from the tooth to the miter slot.Įqual is perfect. With the marked tooth toward the front of the opening in the table, measure the distance from the tooth to the miter slot. Mark a tooth on your blade with pencil or magic marker. If you have a good collection of socket wrenches you will be happy you made the investment, as things like universal sockets, 18" extensions, and floppy head ratchets can make getting to some of the trunnion bolts a lot easier.Ĭrank the blade as high as it will go. You need to loosen all of them to make the adjustment, but leave them tight enough to partially collapse a split type lock washer (the lock washers are usually star type), in other words, tight enough to keep the table snug against casual bumps, but loose enough to be able to move if persuaded. There are four or six bolts that hold the trunnion assembly to the table. If you don't get this done well, you might as well not bother with the rest. The miter slot alignment is the most important part of the process. People that know what a flange is might be able to true it up on the machine with local tools. If you have to ask what a flange is, you had best take it to a machine shop. Again, runout shouldn't be a problem, but the flange might need some work. With the price of Chinese dial indicators in the $20 range, there is no excuse for not having one, so when you get yours, measure both parameters with it. Also, check the flange for true and check for runout. However, not too many of these saws were abused to the point of needing bearing replacement. Fortunately, bearings in this saw are common and easily replaced. There shouldn't be any slop in it, either axial (in the axis of the arbor) or lateral (sideways). Following is a short discussion of each.īefore you take any other steps, check the arbor. I ranked these in order of importance, with pulleys and belt being a tie. Here is a list of the major tasks to make your saw a useful tool:

#Old craftsman table saw manual download

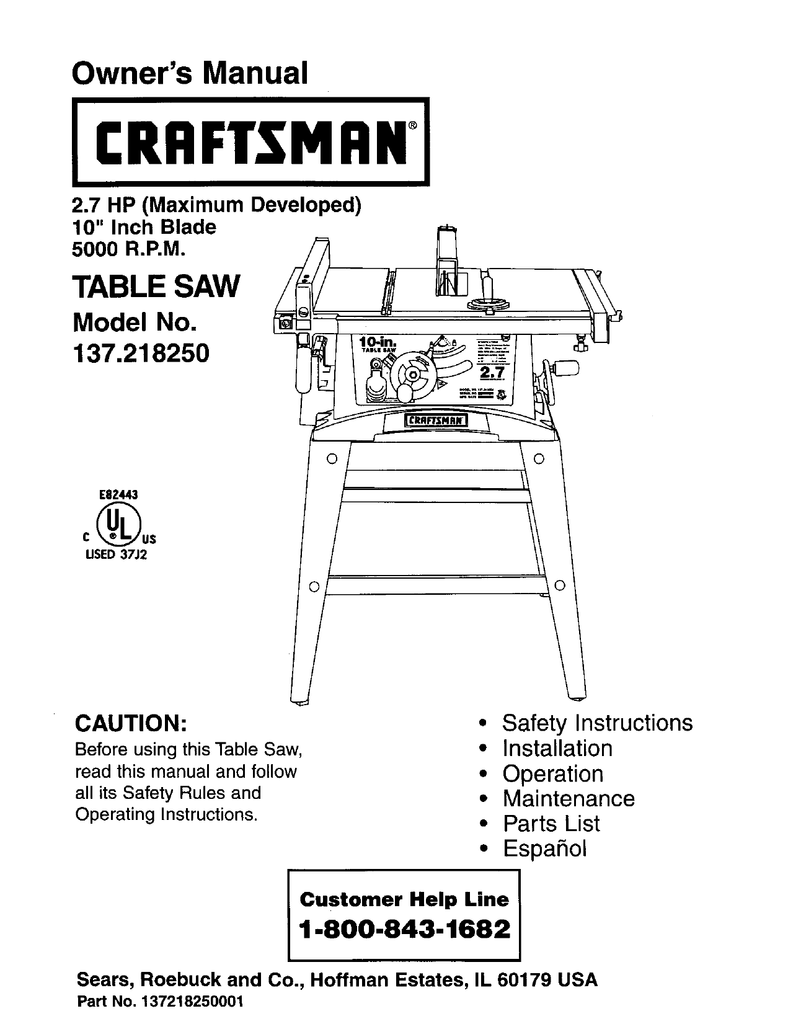

My Sears saw is a vintage 1950s version ( download the manual), but I don't think the design changed much over the years, just some cheapening of some components to maintain a price point. So what else is there? Well, I did it all. Almost everyone has heard of the belts & pulleys improvement, and even PALS are well known now.

#Old craftsman table saw manual upgrade

Quite often the question arises from the new owner of a Craftsman Table Saw, “what can I do to make this thing perform better?” A fence is probably the first upgrade to hit the wallet. But if you are willing to accept some compromises, you can turn an inexpensive product of American mass marketing into a useful tool. On most of the woodworking or tool forums in the internet you will find a lot of Craftsman bashing-some of it richly deserved. It's almost, “if you can't get one of these for $100, you might as well turn in your bargain hunter's badge.” There have been thousands of them sold it seems like there must be one in every garage or basement in America. There is probably nothing so easy to come by cheaply as a Craftsman 10" table saw vintage anywhere from 1950 until last week. Before we get too far into this, let me answer the question posed in the title : You Can't! Get over it.

0 kommentar(er)

0 kommentar(er)